Simplify Your Oversize/Overweight Loads

- Instantly Determine Permit & Escort Costs

- Calculate Max Legal/Permitted Axle Weights

- Understand Equipment Limits

Wind Turbine Transportation | Oversize Wind Blade, Tower and Generator Transportation

1. Introduction

We live in an “energy demanding” nation—electrical energy, that is. There are only so many ways to generate electricity, and each source faces significant challenges. Oil and gas fired generators require fuel with its associated costs and potential pollution. Hydroelectric is relatively clean but there are limited opportunities to build a significant number of hydroelectric dams. Solar panels are increasing in number but are not likely a source of energy for the nation’s power grids.

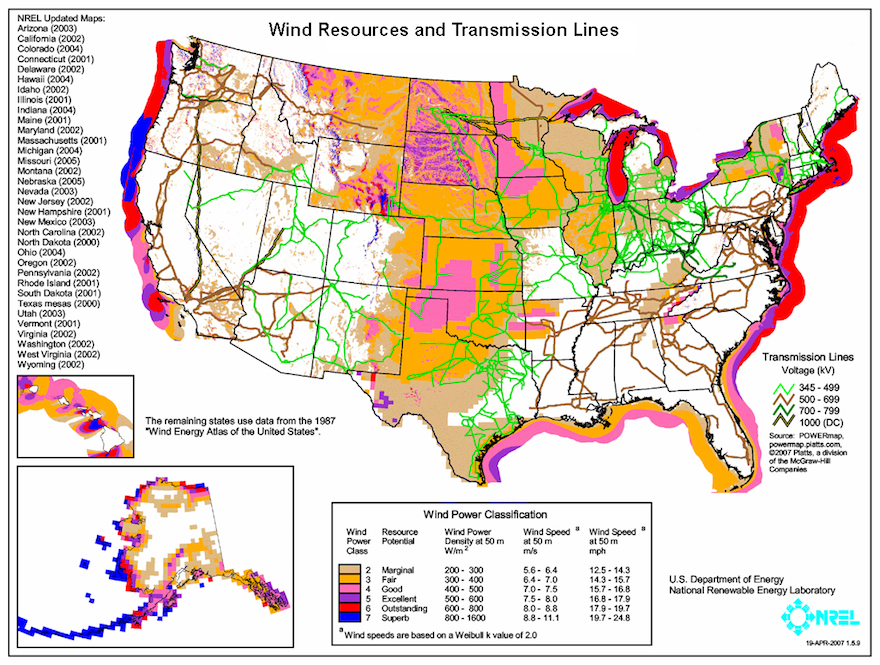

Source: U.S. Department of Energy

Then there is wind energy, captured by large wind turbines organized in groups called “wind farms.” Ideal wind farm sites are locations with frequent and sustained wind currents that can turn the wind turbine blades. But, sustained strong winds are less important with larger wind turbines—larger turbines with longer blades, that reach higher, can be just as effective with lighter winds. And that is the crux of the problem. Transportation of wind turbine structures to wind farm sites, have been increasing in size, length and weight.

2. Brief History

The first windfarm in the United States was built in California beginning about 1980. Today, there are windfarms scattered—coast to coast—across the country, and more are constantly being added. From a distance, driving down a highway beside a wind farm, the size of the “windmills” is not readily apparent. The nacelle that sits atop the tower or pedestal can weigh 75 tons, and the three-blade assembly can weight 36 tons, or about 12 tons per blade. The pedestal, or tower that supports the nacelle, weighs on the order of 24 tons.

All the parts and assemblies that comprise a wind generator must be delivered on trucks. Even if these parts can be loaded on a train, they still must be carried from the nearest depot to the wind farm by truck.

Until recently, most wind turbine parts, including the nacelle, tower, and blades were manufactured in other countries and delivered to ports for distribution in the United States. Due to the demand, several manufacturing facilities have opened in the United States, but the challenge of delivering wind turbine assemblies from the manufacturer to the wind farm still exists.

3. Trends

Currently, the demand for larger wind turbine assemblies is rapidly reaching the point where the demand exceeds the capacity of the nation’s highways and or the number of available trucks to deliver the parts to the wind farms.

Blade size

The early standard for wind turbines is the 1.5 megawatt-GE-built wind turbine. Each turbine can deliver enough energy to supply the needs of 500 homes. The height of the hub of the turbine is approximately 260 feet above ground, supported by the tower, and the highest point of the rotors is 328 feet. Each blade of the rotor is 116 feet long. The diameter of the circle the blade tips make is more than 232 feet or an area equal to approximately 1.5 acres.

The trend is for much larger nacelles and longer blades that extend higher, and operate more efficiently in lighter winds, allowing wind farms to be established in more areas.

Trucking/Hauling

Each of the wind turbine components must be delivered from the port of entry or manufacturer to the wind farm site. Some components can be broken down for shipping, but the blades must the transported as a single piece.

Hauling wind turbine blades that are 116 feet long represents a significantly oversized load. At this length, they are still manageable for transportation by trucks. However, with the trend to larger, taller wind generators, and blades approaching 200 feet long, the truck transportation system is being challenged.

Alternate means of transportation

There has been some use of trains to carry wind generator assemblies. While that offers some potential, it does not solve all the transportation problems. The new, longer generator blades may not fit on typical 89-ft-railroad flat cars. Longer, specially designed cars may be required. Also, the height of some assemblies is taller than railroad underpasses and tunnels. Finally, there is still the challenge of moving the parts from the train depot nearest the wind farm, and the trip from the depot to the wind farm may be the most challenging part of the route.

One potential solution on the horizon is the Lockheed Martin Hybrid Airship that can haul 40,000 pounds of cargo directly to the delivery site. It will have an operational range of 1400 miles. The fact is, it will be some years before this airship will be operational, while the greatest demand is immediate.

4. The Challenges

Demand

At the current rate of growth of windfarms in the United States, the demand for transportation of oversized parts—nacelles, towers, and blades—may exceed both the available trucking resources (power units, trailers, and drivers), and in many cases the highway infrastructure to support loads of the size and weight of newer wind generators.

Current estimates indicate that it costs $100,000 to $150,000 to transport blades from either a port of entry or manufacturer to a wind farm. As component parts of wind generators increase in size, these costs can be expected to increase dramatically.

Wind farms are major engineering projects. Each completed wind turbine represents (1) a major investment, (2) a dependable source of energy for homes and businesses, (3) a source of revenue to the energy company, and (4) a significant engineering and construction effort on a tight schedule. Delays are costly in terms of both construction costs and lost revenue. Timely delivery of components is essential for optimum schedule performance.

To fully support the demands of wind farms, transportation agencies must have the necessary variety of specialized trailering equipment needed to haul exceptionally large and heavy loads over a variety of road conditions—and experienced drivers and crews to manage these exceptional superloads.

Special trailers are required that can be extended to accommodate long blades, and other trailers that can be lowered to carry over-height nacelles and tower sections. Trucks must still adhere to laws limiting the weight carried on any axle arrangement (20,000 lb. for a single axel, 34,000 lb. for tandem axles, see our axle calculator for per state information). Trailers with steer axles may be essential for negotiating sharp turns, especially through intersections.

While longer trailers can accommodate longer, heavier loads, maneuvering these extended trailers is also more challenging, being harder to turn. There is added wear and tear to tires, wheels, and suspensions, as well as the pavement when a sharp turn is required.

Increasing Size and Length

The size and weight are challenging the national transportation system. Many wind farms are located away from main highways and require traveling secondary roads that can be narrow and winding. These roads often travel through small towns. Navigating these roads and the obstacles and obstructions along the route is challenging, time consuming, and expensive.

Permitting

As with any other oversize/overweight load, transport operators must obtain the necessary permits and surveys for each state through which the load will travel. Both the size and weights of these assemblies put many of these loads in a “superload” category of their own. Typically, permitting requires:

- An engineering route survey of the route for: bridges (for weights and axel configuration), grade crossings, overhead obstructions (signs and signals, etc.)

- Review of local traffic patterns

- Provisions to not block emergency vehicle routes

- Dimensional diagram of the load

- Explanation of why alternate transportation is not available

- A practice run of the route

- Compliant escort services (private and/or police escorts)

- Compliant state and local travel schedules

- Seasonal considerations: ice and snow, spring thaw, etc.

- Surety bond

A positive aspect of this is that for a specific route from the manufacturing facility to a specific wind farm site, the permitting process should become repeatable, and less time consuming.

Experience with Small Towns

In some cases, the secondary roads that lead to the wind farm must travel through small towns that can create both roadway and public relations challenges. Streets may have to be widened, or bypass roads must be built. Slower speed community roads may have sharp bends, narrow or no shoulders, or require a sharp turn at an intersection to follow the required route. While the local roads may be passable, it may require closing the roads to other traffic for periods of time to complete the transit. You can find more information about city oversize regulations here.

Drivers

A shortage of drivers is also seen as a challenge. The drivers who haul wind generator components are among the most experienced and capable drivers available, many of whom are approaching retirement age.

Site conditions

Finally, the immediate access roads of the wind farms may be simply gravel roads that serve average vehicles and trucks, but do not support the oversize/overweight loads of trucks transporting wind generator blades, towers, or nacelles. There have been reported instances of trucks bogged down entering the wind farm and requiring heavy lift cranes to assist with loads.

5. The Outlook and Summary

A quick review of the Internet reveals several trucking companies, if not exclusively hauling wind generating equipment, feature that as a major portion of their market. The key marketing features are specialized or dedicated equipment for hauling wind generator assemblies and experienced drivers. Their management is also characterized by detailed planning and the ability to continuously manage multiple tasks.

Several companies are already designing extendable trailers that can accommodate some of the longer blades. Once the blade is delivered, the trailer can be reduced in length so that it is not an over length “load” on the trip back to pick up the next blade.

As the wind farm industry grows, both in numbers and in the size of the wind generators, the transportation infrastructure must also grow and adapt.